IADC Drilling Middle

East 2000 - Muscat, Oman

IADC Drilling Middle

East 2000 - Muscat, Oman Keynote Address

QHSE - Where to Now ?

... "Relationships & Passion"

Tony Allwright, SPE, Tallrite Inc

You can write to to the author by clicking here

Keynote Address

QHSE - Where to Now ?

... "Relationships & Passion"

Tony Allwright, SPE, Tallrite Inc

You can write to to the author by clicking here

![]()

Copyright Tallrite Inc

This paper was prepared for presentation at the IADC Drilling Middle East 2000 Conference held in Muscat, Oman, 21–23 October 2000.

Contents of the paper, as presented, have not been reviewed by the International Association of Drilling Contractors and are subject to correction by the author. The material, as presented, does not necessarily reflect any position of the IADC, their officers, or members. Electronic reproduction, distribution, or storage of any part of this paper for commercial purposes without the written consent of the author is prohibited. Permission to reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of where and by whom the paper was presented. E-mail to tony@tallrite.com.

Note : Click on thumbnails and other links to see enlarged images![]()

I want to explore with you a couple of key elements in the fight to continuously improve Quality, Health, Safety and Environment, that I believe are often overlooked and can have a marked impact. This is a further development of concepts presented in previous papers.1,2,3.

They are "Relationships & Passion", and what I mean by these will become clear by the end of my talk this afternoon.

I’m going to start by talking about Safety, not because it is more important than Q, H & E but because Safety Management is such a trail blazer and is well ahead of the others in terms of maturity. But if we can understand the mechanisms by which we can reach world class performance in safety, the same mechanisms will lead us down the same path for Q, H & E.

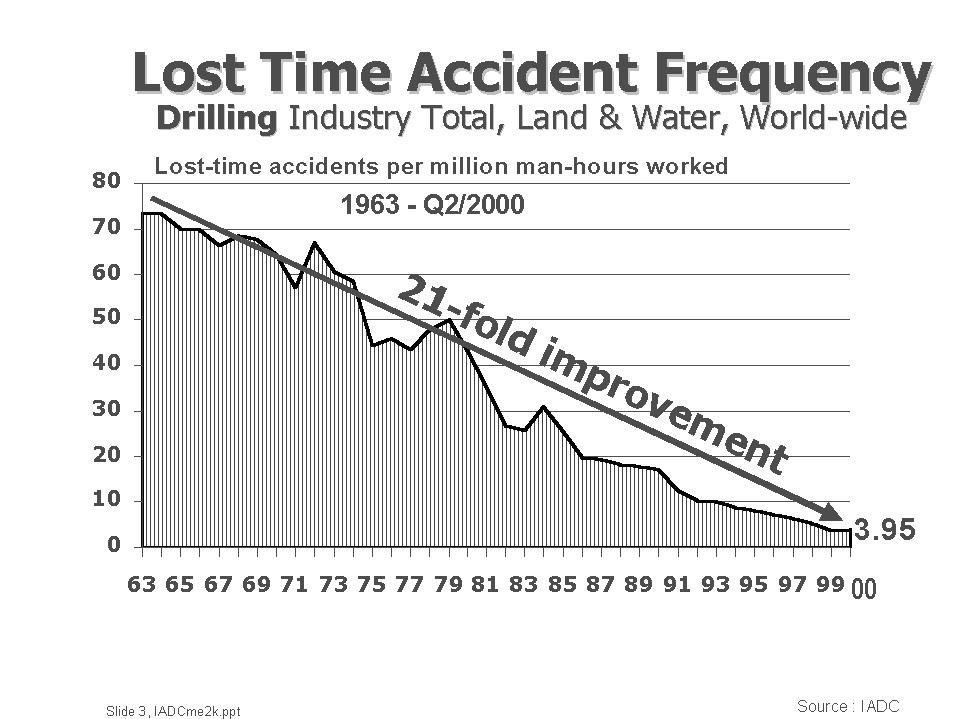

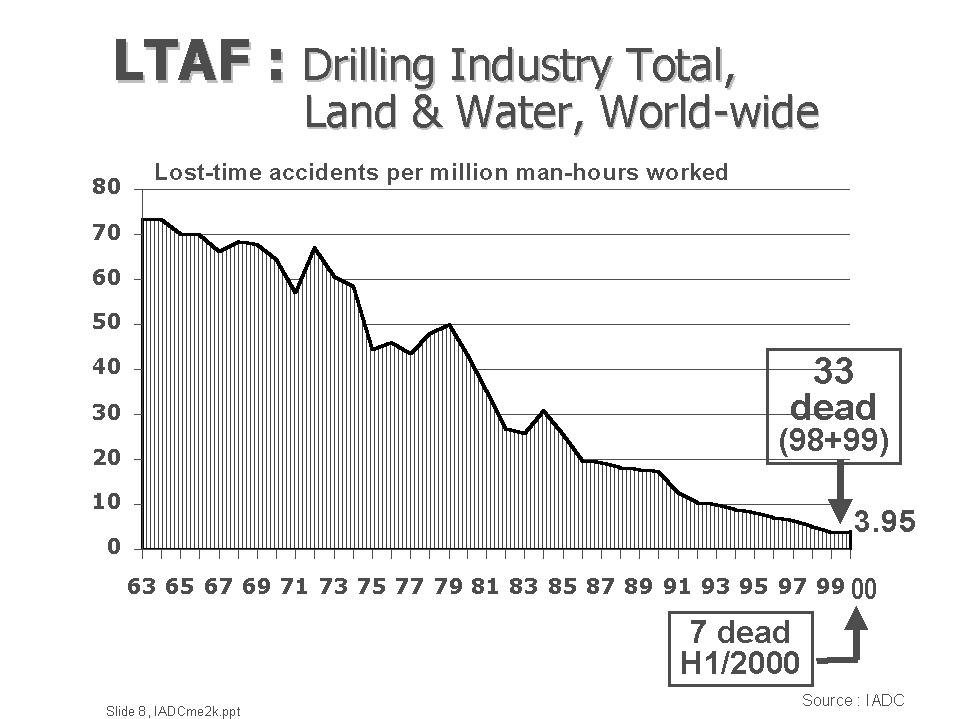

As for Drilling, it is demonstrably a safety leader in Exploration and

Production. Look at the 21-fold improvement in Lost Time Accident Frequency (LTAF) since

records began in 1963 - when with an LTAF of 73 (injuries per million man-hours worked)

one worker in seven got injured every year. Pretty scary ! Today it’s less

than 4 per million.

As for Drilling, it is demonstrably a safety leader in Exploration and

Production. Look at the 21-fold improvement in Lost Time Accident Frequency (LTAF) since

records began in 1963 - when with an LTAF of 73 (injuries per million man-hours worked)

one worker in seven got injured every year. Pretty scary ! Today it’s less

than 4 per million.

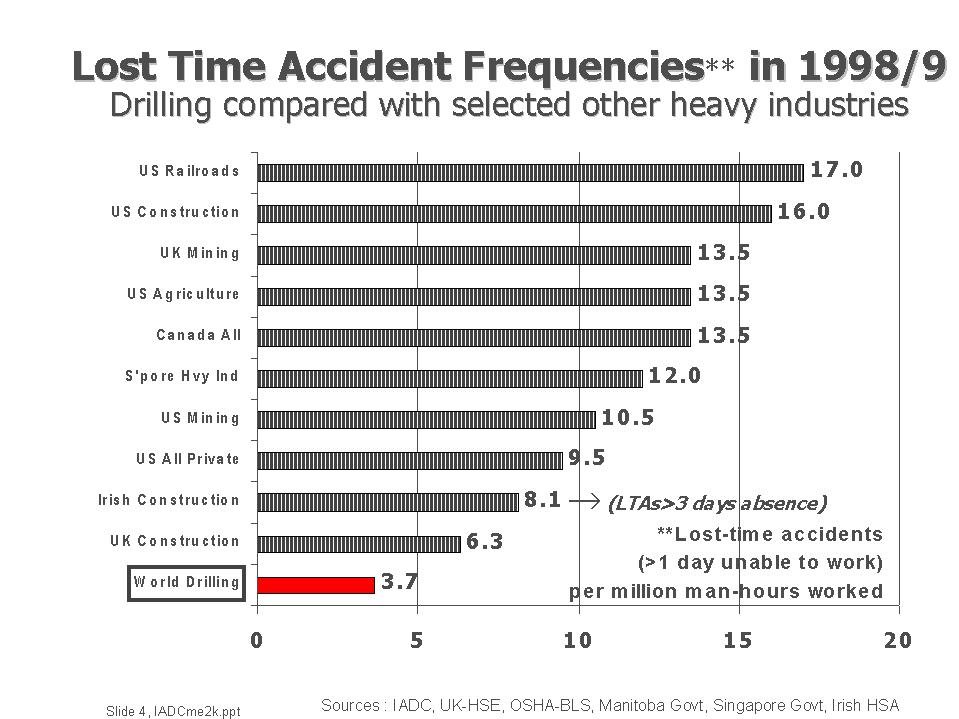

And compared with other non-oil heavy industry it is streets ahead. Undoubtedly, one reason for the success of Drilling is its unparalleled public reporting. No other part of E&P and no other heavy industry has reported its accident figures so honestly and so consistently for so long as the IADC.

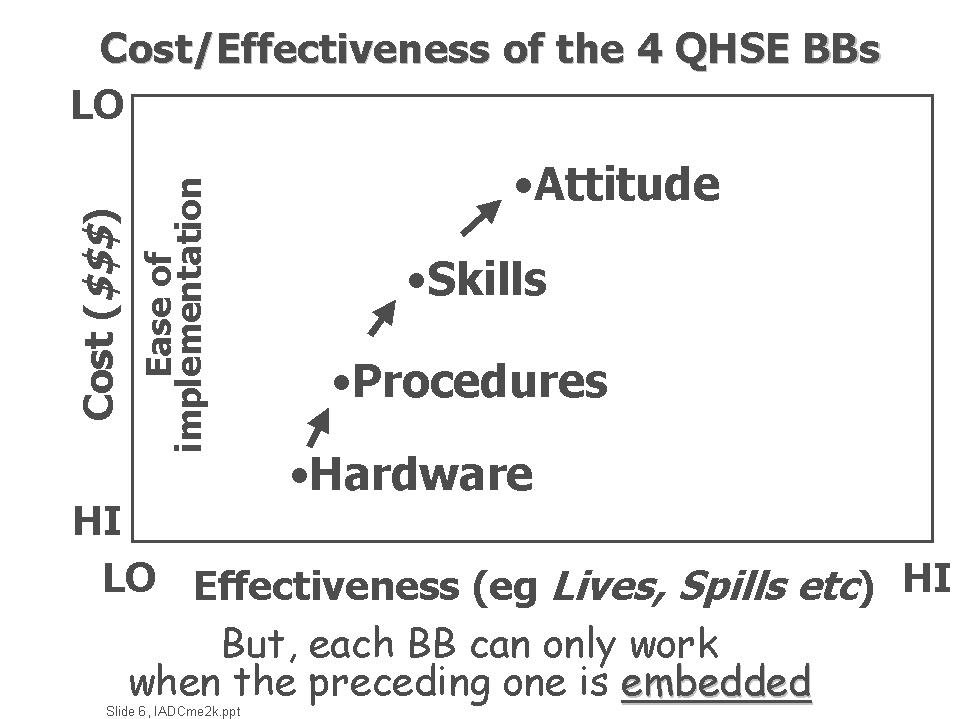

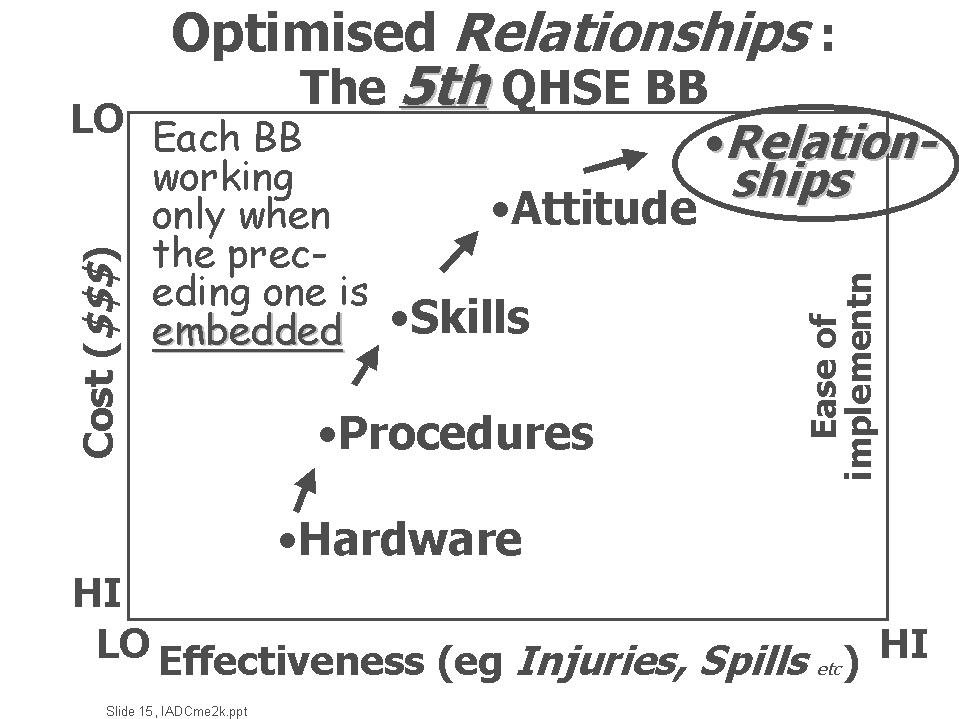

Drilling’s remarkable record has been the result of 4 of what I call "Building Blocks", or BBs, that apply equally for Q, H & E as for Safety, each BB becoming effective provided the previous one is also embedded.

First you must have the right hardware – eg power tools, barriers, non-slip surfaces, iron roughnecks, the humble hard-hat; | |

Then come the right procedures such as for tripping, nippling, using equipment, permit to work systems, etc; | |

Once the right hardware and procedures are in place, people then need to acquire, via all types of formal and informal training and experience, the skills to apply them properly, to identify hazards, to investigate incidents, etc; | |

But this won’t work unless people also have the right attitude - the willingness and motivation of each individual to actually apply the appropriate hardware, procedures and skills that he/she knows are needed to perform the job safely, and to eagerly seek out hazards and rectify them. |

Interestingly, each BB is both cheaper and more effective than the previous one,

however each one gets harder to implement. For example, it is much easier – if

costlier – to write a $1m check for a new piece of equipment than to change a

person’s attitude.

Interestingly, each BB is both cheaper and more effective than the previous one,

however each one gets harder to implement. For example, it is much easier – if

costlier – to write a $1m check for a new piece of equipment than to change a

person’s attitude.

Despite all our industry’s impressive performance, however, we are still

killing too many people – 33 over the past couple of years, 7 in the first half of

this year.

Despite all our industry’s impressive performance, however, we are still

killing too many people – 33 over the past couple of years, 7 in the first half of

this year.

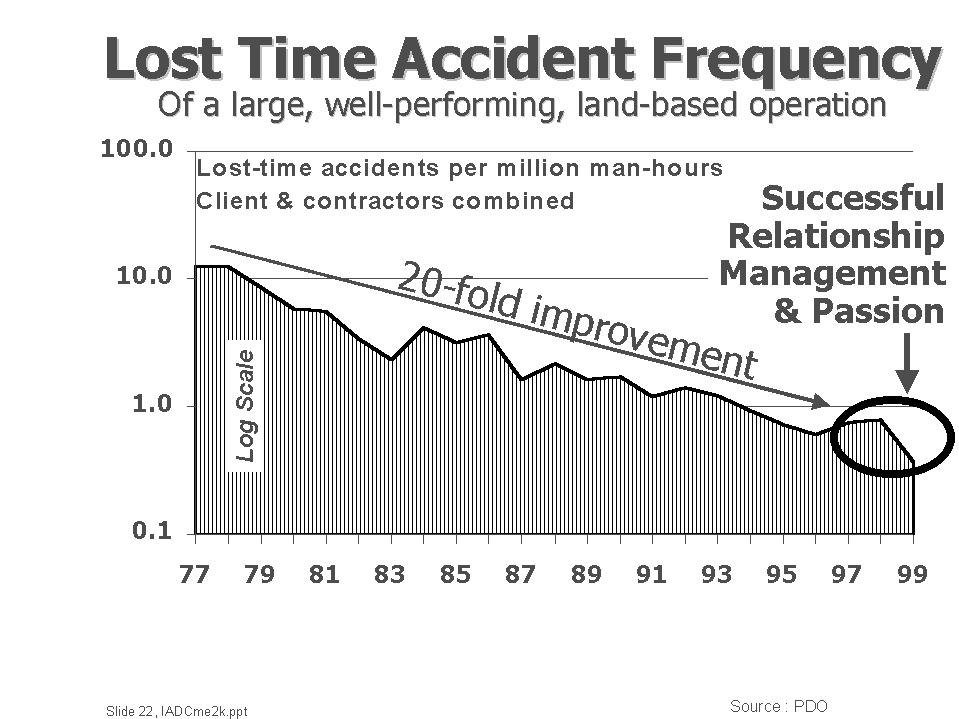

Moreover, the industry’s best performers – those with an LTAF of around 1 – often find their long-term improvement trend flattening out or even reversing.

We have no reason at all to be complacent.

So what can be that fifth BB that appears to be standing in the way of further progress, when the right hardware, procedures, skills and attitude are all firmly embedded ?

Incidents are ultimately caused by human behaviour, which is steered largely by attitude, the fourth BB. But attitude alone provides insufficient direction because it is focused on the individual and his company, the things he/she knows best, and not automatically on the total operation. Similarly, attitude alone will not automatically embrace the separate cultures of different companies.

Indeed the relationship between, in particular, the client and his contractor is often an impediment to high QHSE performance, while nevertheless making both sides comfortable. Typically, the client, because he is providing the money, is over-dominant – he delivers his instructions and then relaxes, believing his work is done. The contractor obeys (often blindly !) and then also relaxes because he feels he doesn’t need to think.

In fact, under this Faustian pact, the contractor’s own ideas and identity are getting suffocated. This might not matter if the client’s solutions were optimum, but they won’t be if they’re not tuned to the culture and identity of the contractor. This is made worse when the contractor works for several clients making different demands – no wonder his people often end up confused despite superb attitude.

What each Client, Contractor and Sub-Contractor needs in equal measure is his own QHSE policy, management system, plans etc, amounting to a philosophy of "this is how we do things around here". Each needs to come up with his own QHSE ideas that will help both himself and his clients in their joint quest for optimum QHSE solutions. Each needs to take full ownership and responsibility for pushing his own QHSE message, and to accept, without quibble, his own QHSE mishaps.

Each needs to be prepared to change his behaviour.

The Contractor needs to do the right things not because Client demands it but because he believes in it. He should make clear to his people that this is what this company demands, and not simply wait for the client’s say-so. He must not confuse his people by setting different standards for different customers, and most importantly he must have the courage to tell his Client what he thinks the Client is doing wrong.

But none of this is realistic unless the

Client also changes his behaviour. Above all, the Client must listen to and respect the

views of his Contractors, recognizing that their answers may be superior. He should

encourage his Contractors to take key decisions (eg to lead task forces or investigations)

and should always combine Client & Contractor statistics. In short, in QHSE matters,

the Client needs to treat all his contractors and sub-contractors on a wholly

equal footing with himself, placing no party on a more important level than

any other (including himself).

These behaviour changes, which will be very difficult for all, and radical for many, amount to the missing fifth building block, Relationships, meaning the mutual management of the client/contractor relationship in the interests of optimising QHSE performance.

Managing the client/contractor relationship entails a process of continuous communication up, down and sideways, within and between all companies involved in the operation. It means each party listening open-mindedly to the views of the others. It means ignoring pecking order, seniority, status etc, and using only the force of rational argument to arrive at QHSE solutions that are both optimum and agreeable for all parties.

Responsibility for managing the relationship rests squarely with the senior managers of all the companies involved in the operation. It is they who should initiate and provide impetus for the multidirectional communication required both within their respective companies and between the different companies. A first step might be to organize a joint conference for the senior and middle managers of the client and all his contractors and sub-contractors. This conference would identify QHSE problems, blockers etc, develop cross-company teams to tackle them, devise action plans, set time-scales, establish communication strategies and so forth.

Meanwhile, however, despite what the bosses are (or are not !) doing, any member of staff can and should discuss with his/her peers and counterparts and press for change from within. When it comes to QHSE, there is no need to wait for the boss or the client before embarking on improved relationships and setting the example for others.

And the cost of all this ?

In hard cash, comparatively little. Relationship management is about changing corporate behaviour, which is made to happen when employees – that is, all of them but especially the bosses - expend not money but their personal effort, belief, nervous energy, commitment. In other words, they are possessed of a driving personal passion.

Passion is a difficult emotion. It combines agony with ecstasy.

Someone with a genuine passion for QHSE

might possess a mind constantly roaming for solutions; suffer an aching knot in the

stomach; he might deliberately make QHSE activities a "nuisance" and

"intrusion" on his other activities; certainly he walks the talk; he takes

genuine delight at QHSE achievements and milestones; experiences personal pain at

another’s loss or at environmental damage; sleepless nights sometimes intrude; yet he

also has the ability to relax and enjoy life’s good things. And through his personal

behaviour he inspires others with similar passion.

Relationships and passion – they are hard but they do work. A full year where these were vigorously pursued throughout the organisation resulted in a step change improvement in safety performance in 1999 for a high-performing company (LTAF <1) that had suffered trend reversals over the previous two years.

However, maintaining the relationships and

passion at the necessary level is extremely tough and it is easy to slip back again as

seemed to be happening by mid-2000. ![]() Though this has acted as a sharp spur to regain the gain by the end of the year.

Though this has acted as a sharp spur to regain the gain by the end of the year.

Meanwhile, where do gyrating rig-counts, oil-prices and other external business factors figure in all this ?

They change nothing because QHSE performance is part of overall business integrity, just as vital whether times are good or bad. No board or shareholder will tolerate lack of financial integrity, meaning business controls, or lack of the technical integrity than keeps the assets running smoothly. Most responsible boards, not to mention the society in which business is conducted, will be equally unforgiving if QHSE performance demonstrates a lack of integrity – that is, a failure to continuously and measurably improve – regardless of the contemporaneous business climate. For this reason, Integrity in its widest sense should and often does form a part of every company’s business objectives.

So, in conclusion, to the question "QHSE - Where to Now ?", and assuming you have already embedded the first four Building Blocks into your respective organizations, I would respond to each of you here present,

|

|

In short, Relationships and Passion.

Thank you for your attention

![]()

References

Krahn, Dennis R, Mearns, Charles S., Richards, Simon C.H., "The UK Cross Industry Safety Leadership Forum - A Drilling Sector Perspective", paper SPE 61046 presented at the SPE International Conference on Health, Safety, and the Environment in Oil and Gas Exploration and Production held in Stavanger, Norway, 26–28 June 2000

![]()